THE RIGHT TOOL MAKES ALL THE DIFFERENCE

STRAND JACKS

Hydraulic press capacities range from 17-ton to 955-ton

A strand jack is a linear winch system used for lifting heavy loads, common in the construction industry for bridges and large projects. Enerpac’s models range from 17 to 995 imperial tons per jack, offering precise lifting with a smaller footprint compared to cranes. Operated by a hydraulic jack, it utilizes a bundle of steel strands for controlled lifting and lowering. A single operator can synchronize multiple strand jacks through computerized control. Key components include the hydraulic jack, top and bottom mini-jacks, strand guide tubes, and counter-balance valve for safety and controlled operations during lifting and lowering.

ENERPAC STRAND JACKS

17- 955 TON Capacity

What Is a Strand Jack?

A strand jack is a type of linear winch system used for pulling heavy loads from above. They are widely used in the heavy construction industry, especially for bridges, ports, and large-scale plant maintenance projects.

Lifting capacities vary depending on the models used. For example, The capacity range of Enerpac Strand Jacks is from 17 up to 1405 imperial tons (150 to 12500kN) per jack.

The main benefits of a strand jack over a crane are a much smaller footprint, and the ability to lift and lower with more precision. In addition, a single operator can control several strand jacks synchronously via computerized control from a central location.

Integrated Strand Guide

Helps to keep the strands in position when exiting the jack

Main Hydraulic Jack

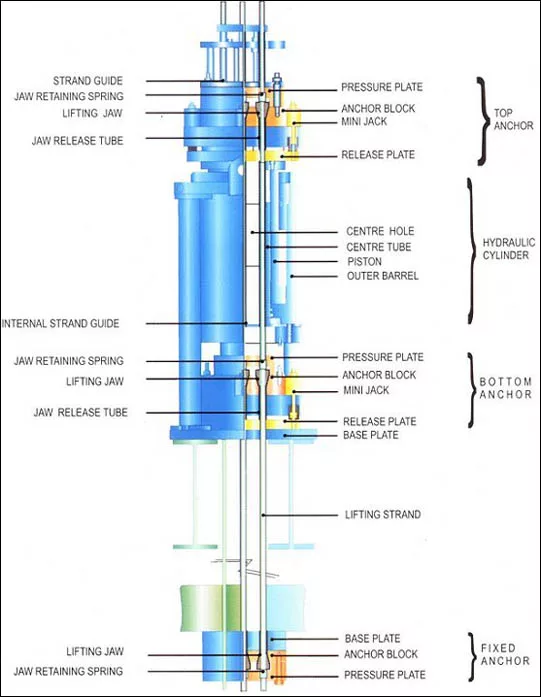

The hydraulic jack (cylinder) is the heart of the strand jack. Depending upon the model, this can extend and retract as much as 600mm (23.6 inches) with each stroke.

Top and Bottom Mini-Jacks

These include the anchor systems used to lock and unlock the strands. Each is automated and includes wedges, springs, and hydraulics.

Strand Jack Wedges

These are wedges used to grip the strands. The wedges lock and unlock on the strand through hydraulic pressure applied by the mini jacks. They are replaceable, and although long-lasting can be considered as consumables.

Strand Guide Tubes

Telescopic strand guide pipes keep the strands apart, and prevent ‘bird caging’.

Counter-Balance Valve

This serves two functions. The primary purpose is to provide load holding in the event of hose failure. It also provides smooth controlled lowering of the load.

Chair

The base of the strand jack, which is fixed onto the supporting platform.

How a Strand Jack Works

If you’ve ever pulled on a rope to lift or drag a load this will help you understand the working principle. Like your hands would do on a rope, they use a similar sequence of locking, pulling, and unlocking at the top and bottom of the strand jack, but instead of using a single rope, there can be anything betwHow Does a Strand Jack Work?een 1 to 84 steel strands included (the strand bundle). The strand jack is commonly positioned vertically on a support beam above the location where the load needs to be lifted, however, they can also be used in the horizontal orientation.

The lifting or lowering action is performed by a large hydraulic jack (cylinder) that extends and retracts while the top and bottom anchor systems in turn lock onto each strand, guiding them through the hollow cylinder.

Towerlift

Towerlift is an extremely heavy duty structural support system for use with strand jacks. It is specifically designed in modular form for ease of assembly, erection and worldwide transportation. In its basic form it is assembled from only two members – legs and bracings. Bracings are connected

to the legs by means of a single pin at each end. Two sets of connection points are provided on all legs so that the same members may be assembled in either three-leg triangular or four-leg square format towers. The design philosophy is to provide a support structure which requires minimal external guying for reduced site disruption.

Because of its unrivalled versatility as a temporary support structure, Towerlift can be used in varying ways to produce the most economicallifting arrangement.

Examples of typical formats are: paired towers with crosshead beams; four-square towers with crosshead beams; towers with tied cantilever beams; independent luffed towers; portalised luffed towers.

Strand Jacks

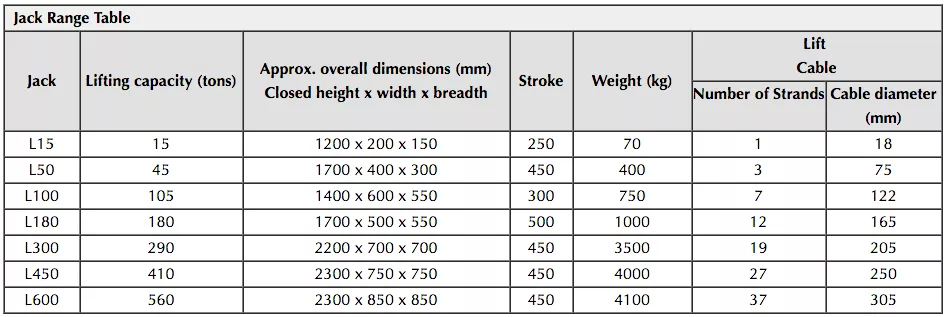

We operate a range of jacks from 15 to 560 tons capacity each based upon lift cables of 1 to 37 strands of 18mm diameter, 7 wire, die-compacted, prestressing strand of guaranteed minimum breaking load of 38 tons per strand.

Jacks may be used singly, in pairs, or in groups to give any lifting capacity required.

Power Packs

We operate a large fleet of purpose built diesel-hydraulic and electro-hydraulic power packs.

All have multiple outlets of matched flow which automatically ensures synchronized operation speed of jacks connected to each of these outlets.

In addition to main hydraulics, they also deliver flow for operation of the secondary hydraulic systems which controls jack gripping mechanisms. From this fleet, we are able to select power pack and jack combinations to meet all functional requirements of synchronized lifting by multiples jacks at appropriate lifting speeds.

Monitoring and Control Systems

All power packs have direct, panel mounted, monitoring and control systems.

It would be typical that an operator might control a multi-jack lift or lower by means of two functional control levers on the power pack with the option of opening or closing hydraulic flow to all or any of the jacks at any stage by means of line valves.

Maximum pumping pressure, hence jack lifting force, can be pre-set or altered at will by pressure control valves on the panel.

All pumping pressures to each jack, and each jack’s secondary hydraulics pressure, are displayed on panel gauges.

Further electronic monitoring can display number of lift strokes completed and individual stroke positions on each jack.

Similar control and monitoring facilities can also be positioned remote from the power pack to fully computerized systems, including automatic lifting and lowering capabilities.

Advantages

Comprehensive, completely automatic, remote control and monitoring is as practical reality in our system which enables benefits such as:

- Mechanically fail-safe gripping mechanisms

- Pre-set overload protection

- Automatic synchronization of lifting speeds irrespective of loads

- Ample operating speeds

- Load is held mechanically not hydraulically at any time movement is stopped

- Movement can be stopped and held indefinitely at any point in jack stroke

- Extremely precise adjustment of the lift for setting of weld gaps or the fitting of steelwork connecting bolts

- Automatic lowering without any personnel in attendance at the jacks

- Ready re-distribution of the jack loads

- Minimal re-lubrication of gripping mechanisms – lifts of 90 meters and horizontal moves of 250 meters have been completed without the need for re-lubrication

- Gripping mechanisms are fully accessible at all times

- Full efficiency in all attitudes from vertical through to horizontal

- Completely self contained and very rugged.